COLUMN

Ultrasonic Cutter / Polisher columns

26/07/2018 Category:Ultrasonic Cutter

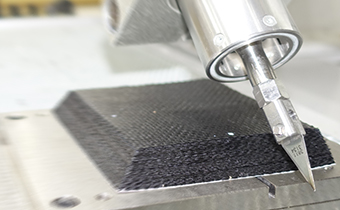

Ultrasonic Cutter Mechanism(regarding oscillator)

Amplitude value of blade can be set by volume of amplitude in the front panel of oscillator. By performing feedback control, the set amplitude of the cutting edge is kept constant irrespective of the change of the mechanical load (cutting resistance). When an external load…Learn more

26/07/2018 Category:Ultrasonic Cutter

Ultrasonic Cutter Mechanism(regarding blade)

There are two types of blade materials, “High Speed Steel” and “Tungsten Carbide” Compared to high-speed blades, tungsten carbide blades have high rigidity and durability, but since they are heavy, the burden on the oscillator increases. The thickness ranges of blades are…Learn more

26/07/2018 Category:Ultrasonic Cutter

Ultrasonic Cutter Quality

Changes in the cutting resistance applied to the blade were investigated by the presence or the absence of ultrasound and the changes in the parameters of the amplitude value, the cutting speed, and the vibrator tilt angle. <<Experiment was conducted under the following…Learn more